The integration of NIRLAB’s portable NIR spectrometer heralds a significant leap in textile manufacturing. This by aligning the precision of Near-Infrared (NIR) spectroscopy with the complex demands of textile quality assurance. This breakthrough enhances the efficiency and accuracy of fiber identification, moisture content analysis, and verification of chemical finishes. Hence, ensuring fabric consistency, safety, and compliance with industry standards. NIRLAB’s solution transcends a mere analytical tool; it empowers manufacturers with the confidence to make immediate, informed decisions about textile quality, rapidly identifying and quantifying key fabric components without damaging the material.

This approach minimizes risks associated with fabric degradation and preserves the integrity of textiles. Moreover, it helps building consumer trust through transparent, evidence-based practices. Furthermore, it aids the industry’s adherence to stringent safety measures and regulatory frameworks by providing reliable data crucial for quality validation and market readiness.

Setting Up for Success: The NIRLAB Approach

NIRLAB’s spectrometer is crafted for simplicity and effectiveness, making it an essential tool for the textile sector:

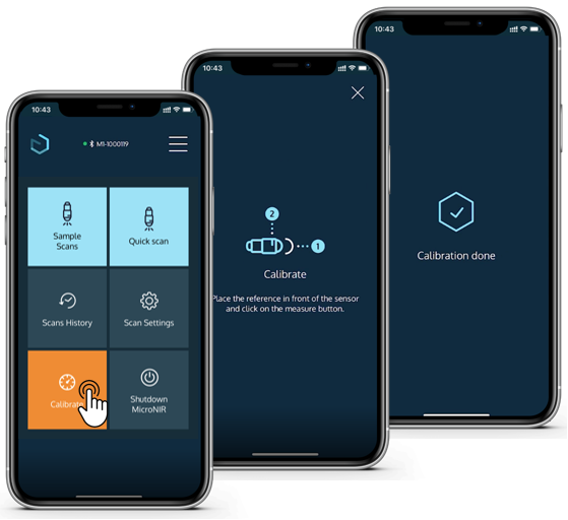

- Pair and Prepare: Seamlessly connect the NIRLAB app with the spectrometer by activating the device, launching the app, and enabling Bluetooth pairing. This facilitates a smooth transition to fiber analysis without technical interruptions.

- Calibration is Key: Start each session with calibration using the white reference mirror to ensure accurate fiber readings. This is a quick process assisted by the app to ensure your data’s integrity.

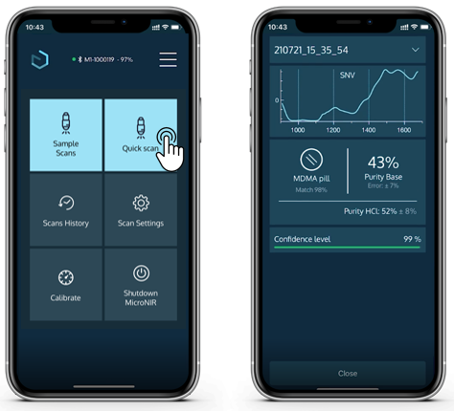

- Choose Your Scanning Mode: Opt from two scanning modes designed for textile quality assurance. Quick Scan offers rapid fiber profiles, while Sample Scan averages multiple readings for higher accuracy. It is critical for comprehensive fiber analysis and quality control.

Understanding Scanning Modes

Each mode addresses specific needs:

- Quick Scan: Best for on-the-spot testing, delivering rapid fiber profiles to keep production moving.

- Sample Scan: When accuracy is crucial, such as in final product quality control or detailed fiber analysis, this mode provides a thorough breakdown.

For a comprehensive list of fibers and components that can be analyzed using NIRLAB’s spectrometer, we invite you to reach out to us at contact@nirlab.com

Scanning Without Direct Contact

NIRLAB’s spectrometer is able to scan through non-invasive barriers like fabric packaging. This is invaluable for maintaining textile sample integrity and safety, critical for consumer safety and regulatory compliance.

Maximizing Accuracy and Safety

Maximizing Accuracy and Safety

- Substance Measurement: NIRLAB recommends measuring all textiles either in direct contact or through thin packaging. However, with direct contact providing the best accuracy, especially for quantitative analysis.

- Cleaning the Sapphire Glass: Users are advised to clean the sapphire glass before each scan to maintain the scanning surface’s integrity. This will ensure optimal performance.

- Homogeneity Assessment: For textiles and large quantity samples, the Sample Scan mode is recommended to better evaluate homogeneity.

- Small Samples: Measuring small samples in an aluminum cup, which does not affect the spectrum, is recommended for best results.

- Device Orientation: For optimal outcomes, users should point the device downwards during scanning. Hence, measuring with the device pointing upwards is discouraged.

- Addressing Unidentified Textiles: If the device displays “unknown textile,” performing several scans from different positions around the sample is recommended for a comprehensive analysis.

- Preserving Sample Condition: Ensuring accurate readings involves scanning textiles in their original state, without altering their condition.

- Optimized Scanning Practices: Consistent and accurate scans are achieved by ensuring the sample is either in direct contact with the device or within a narrow separation of 1-2 millimeters. Utilizing a small aluminum cup can further enhance the scanning process.

Optimizing Textile Quality Assurance: The NIRLAB Spectrometer Advantage

NIRLAB’s spectrometer emerges as a transformative tool in the textile industry, offering unparalleled precision and adaptability in fiber analysis. Its introduction signifies a new era of sophistication in quality control and product development for textiles. This advanced technology facilitates quick, detailed fiber profiling, empowering manufacturers to meet and exceed expectations for high-quality, consistent textile products.

The spectrometer’s intuitive design ensures a seamless setup. By allowing for immediate use in a range of textile applications, from raw material verification to finished product inspection. Moreover, by choosing between Quick Scan for fast results or Sample Scan for enhanced detail, textile professionals can access reliable, real-time data essential for informed decision-making throughout the production process—optimizing raw material selection, verifying fabric composition, and ensuring the quality of the final product.

NIRLAB’s spectrometer analyzes textiles without touching them, a key advantage in the industry. This avoids fabric damage and keeps products intact. It also meets hygiene and safety standards expected by consumers and regulators. Thus, the device ensures compliance and prepares manufacturers for future changes and advancements.

Incorporating NIRLAB’s spectrometer into their quality assurance processes, textile businesses underscore their commitment to innovation and evidence-based practices. This commitment is essential in an industry where consumer trust is crucial, and the competition to deliver superior products is intense. By leveraging such technology, textile businesses can ensure fabric consistency and safety, fundamental for consumer confidence and brand reputation.

As the textile industry continues to evolve, the adoption of advanced technologies like NIRLAB’s spectrometer is set to become a standard practice, establishing a benchmark for product quality. This tool not only reshapes the landscape of fiber profiling but also acts as a cornerstone for the future of textile quality control, strengthening the link between scientific innovation and commercial success.

Explore Our Diverse Range of Applications: More Solutions at Your Fingertips!

NIRLAB’s spectrometer extends its application beyond textiles, proving to be an invaluable asset across various sectors. To learn how our technology is being utilized for harm reduction, polymer analysis, and enhancing law enforcement operations, visit our “Practical Guides/How to” section on www.NIRLAB.com/blog

To delve further into the world of spectroscopy and discover the full capabilities of NIRLAB’s technology, we invite you to explore our other insightful articles, here. For personalized inquiries, reach out to us at contact@nirlab.com.

NIRLAB // Just Truth