The integration of NIRLAB’s mobile NIR spectrometer marks a pivotal advancement in the Polymer industry. This by harnessing the accuracy and depth of Near-Infrared (NIR) spectroscopy to meet the industry’s complex demands. This leap in technological application enhances the efficiency of polymer analysis, crucial for quality control, ensuring consistency, safety, and adherence to industry standards. Beyond being a mere analytical tool, NIRLAB’s solution equips manufacturers with the capability to make swift, accurate decisions regarding polymer composition and quality by rapidly identifying and quantifying polymer constituents without needing direct contact with the material.

This minimizes contamination risks and maintains the integrity of the polymers, fostering industry-wide trust through transparent, evidence-based operations.

Setting Up for Success: The NIRLAB Approach

NIRLAB’s spectrometer is engineered for ease and efficiency, proving indispensable in the polymer industry:

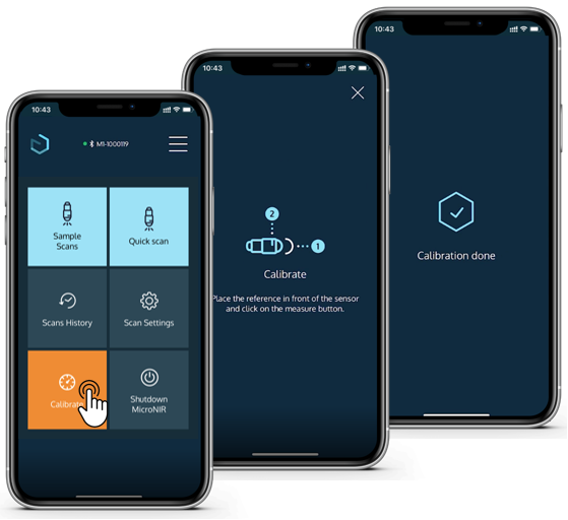

- Pair and Prepare: Establish a connection between the NIRLAB app and the spectrometer with ease—simply turn on the device, launch the app, and engage Bluetooth for automatic pairing, facilitating a hassle-free transition to polymer analysis.

- Calibration is Key: Regular calibration with the white reference mirror is essential for precise readings. The app’s guided process ensures your analyses are accurate and reliable, providing confidence in your quality control protocols.

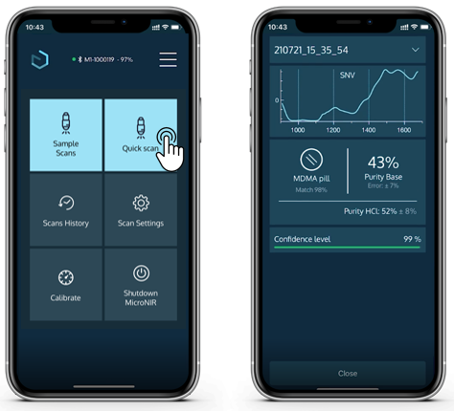

- Choose Your Scanning Mode: The spectrometer offers specialized scanning modes. Quick Scan yields rapid results for routine checks, while Sample Scan aggregates multiple readings for more complex or detailed analyses, vital for ensuring the quality of polymers across batches.

Understanding Scanning Modes

Each mode serves a distinct purpose:

- Quick Scan: Use this mode for immediate analysis, perfect for high-throughput environments where time and efficiency are of the essence.

- Sample Scan: Select this mode for comprehensive analysis when dealing with complex polymer matrices or when more detailed information is required for quality control measures.

For a comprehensive list of polymers that can be analyzed using NIRLAB’s spectrometer, visit our extensive polymer substance list. This guide provides detailed insights into the wide range of polymers our technology is capable of analyzing, ensuring that you can apply NIRLAB’s precision to your specific materials.

Scanning Without Direct Contact in Polymer Analysis

One of the spectrometer’s key features is its ability to scan without direct contact, preserving the purity of polymers and maintaining a contamination-free environment, which is essential for accurate quality control and compliance with regulatory standards.

Maximizing Accuracy and Safety

To obtain the best results, follow these recommendations:

- Substance Measurement: NIRLAB advises that all substances can be measured in direct contact or through thin plastic, with direct contact yielding the best accuracy, particularly for quantification.

- Cleaning the Sapphire Glass: Maintaining the integrity of the scanning surface, users are advised to clean the sapphire glass before each scan. A simple process involving a bit of ethanol on a tissue ensures optimal performance.

- Homogeneity Assessment: For powders and high quantity samples, the Sample Scan mode is recommended to better assess homogeneity.

- Small Samples: NIRLAB recommends measuring small samples in an aluminum cup, which has a neutral effect on the spectrum.

- Device Orientation: To ensure optimal results, users are advised to point the device downwards during scanning, as measuring with the device pointing upwards is not recommended.

- Troubleshooting Unidentified Samples: Should the device display “unknown substance,” it is recommended to perform several scans from various positions around the sample.

- Preserving Polymer Sample Authenticity: For accurate analysis outcomes, polymer samples should be scanned in their original, unmodified state.

- Optimized Scanning Practices: For reliable and precise scans, the sample should either be in direct contact with the device or placed within a 1-2 millimeter proximity. Using a small aluminum cup can assist in achieving these conditions.

Optimizing Polymer Operations: The NIRLAB Spectrometer Advantage

NIRLAB’s spectrometer is a transformative asset in the polymer industry, delivering unmatched precision and versatility in polymer analysis. Its market introduction heralds a shift towards more sophisticated quality control and product development within the industry. This state-of-the-art technology enables swift, detailed polymer profiling, empowering manufacturers to consistently produce high-quality polymers.

The spectrometer’s user-friendly design guarantees quick integration into any polymer manufacturing process, from quality control labs to production lines. With the choice between immediate or detailed analysis, polymer professionals can access precise, real-time data crucial for critical quality decisions.

The spectrometer’s non-invasive analysis capability is particularly advantageous for maintaining the high standards required in polymer production. This technology supports compliance and future-proofs manufacturing processes against evolving industry standards and regulations.

Implementing NIRLAB’s spectrometer in quality assurance workflows signifies a commitment to advanced, data-driven practices. This commitment is critical in a sector where quality and trust are non-negotiable, and competition drives the need for innovation. By adopting this technology, polymer businesses can guarantee the consistency and safety of their products, cementing consumer confidence and enhancing brand integrity.

As the polymer industry continues to innovate and expand, adopting advanced technologies like NIRLAB’s spectrometer will likely become a norm, establishing a standard for product excellence. This tool not only transforms the framework of polymer analysis but also becomes a cornerstone for future quality assurance, bridging the gap between scientific innovation and industrial application.

Explore Our Diverse Range of Applications: More Solutions at Your Fingertips!

NIRLAB’s spectrometer extends its application beyond polymers, proving to be an invaluable asset across various sectors. To learn how our technology is being used for harm reduction, cannabis quality control, and enhancing law enforcement operations. By clicking on the links, you can find detailed setup guides, user experiences, and the impact of NIRLAB’s technology in these fields.

To delve further into the world of spectroscopy and discover the full capabilities of NIRLAB’s technology, we invite you to explore our other insightful articles, here. For personalized inquiries, reach out to us at contact@nirlab.com.

NIRLAB // Just Truth