In the evolving landscape of waste management recycling and polymers, Near-Infrared Spectroscopy (NIR spectroscopy) stands out as a transformative technology. Its relevance in plastic sorting, recycling, and waste management cannot be overstated. NIR spectroscopy offers a rapid, non-destructive method to identify different types of plastics. Each plastic type has a unique NIR light reflection pattern, enabling precise classification. This accuracy is crucial for maintaining the quality of recycling processes and avoiding contamination of recycled materials. Furthermore, NIR spectroscopy streamlines sorting processes, reducing the need for manual labor, thus lowering operational costs. Significantly, its application in efficient plastic sorting plays a vital role in reducing environmental pollution by enhancing recycling rates. Versatile and adaptable, NIR spectroscopy is indispensable in modern waste management, contributing greatly to sustainability.

Polymer detection

Our handheld spectrometer is at the forefront of this technological revolution, capable of identifying over 50 different polymers in various forms, such as plastic rods, granules, foils, and plates. It adeptly handles diverse colors and surface textures, whether rough or smooth. The device’s substance library covers a broad range of polymers, including the “big five”: PE (Polyethylene), PP (Polypropylene), PS (Polystyrene), PET (Polyethylene Terephthalate), and PVC (Polyvinyl Chloride).

It also encompasses other polymers like ABC, POM (Polyoxymethylene), PMMA (Polymethyl Methacrylate), EVA (Ethylene-Vinyl Acetate), PC (Polycarbonate), TPR (Thermoplastic Rubber), and more. Additionally, our solution offers the capability to distinguish between similar polymers like PA6 and PA66 and to classify subtypes of Polyethylene, such as LDPE, HDPE, and MDPE.

Our database is dynamic and ever-expanding. As new polymers emerge, they are swiftly added to our library, making them immediately accessible to all users. We continually update our database to reflect the latest advancements in polymer technology and recycling practices.

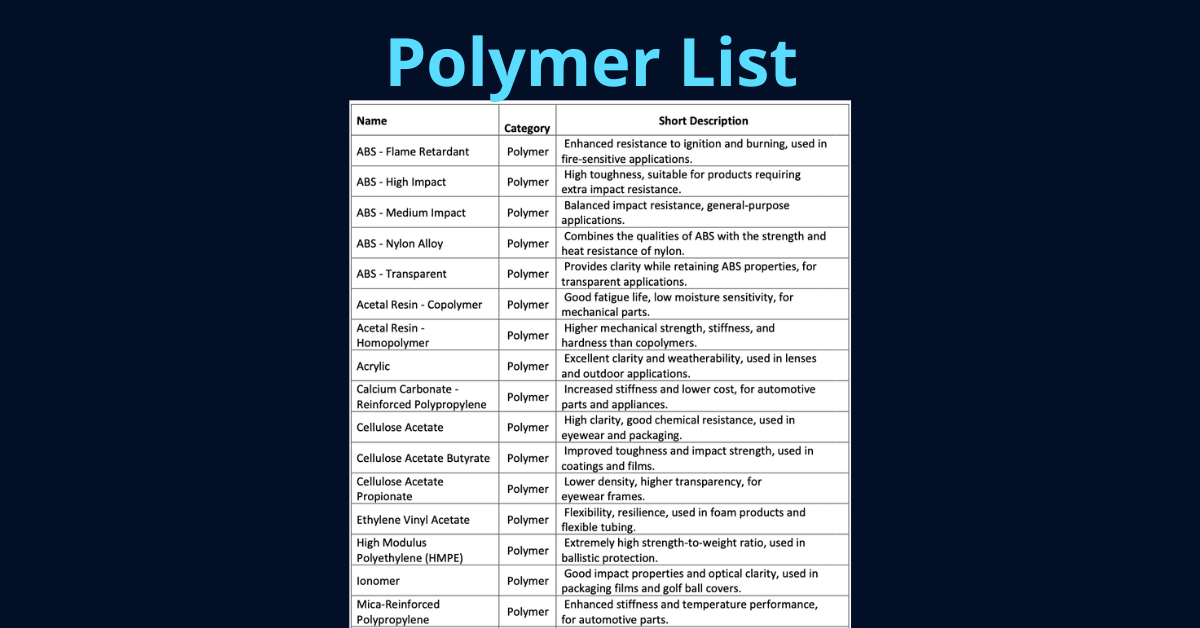

Incorporation of the Full List (as of 15.06.23)

In our overview below, we’ve highlighted our detailed polymer catalog. This evolving document is a demonstration of our commitment to comprehensive detection and meticulous analysis.

For stakeholders seeking more detailed information or with specific inquiries about our capabilities, our dedicated team is ready to provide the latest insights and individualized assistance. Please contact us here.

| Name | Category | Short Description |

| ABS – Flame Retardant | Polymer | Enhanced resistance to ignition and burning, used in fire-sensitive applications. |

| ABS – High Impact | Polymer | High toughness, suitable for products requiring extra impact resistance. |

| ABS – Medium Impact | Polymer | Balanced impact resistance, general-purpose applications. |

| ABS – Nylon Alloy | Polymer | Combines the qualities of ABS with the strength and heat resistance of nylon. |

| ABS – Transparent | Polymer | Provides clarity while retaining ABS properties, for transparent applications. |

| Acetal Resin – Copolymer | Polymer | Good fatigue life, low moisture sensitivity, for mechanical parts. |

| Acetal Resin – Homopolymer | Polymer | Higher mechanical strength, stiffness, and hardness than copolymers. |

| Acrylic | Polymer | Excellent clarity and weatherability, used in lenses and outdoor applications. |

| Calcium Carbonate – Reinforced Polypropylene | Polymer | Increased stiffness and lower cost, for automotive parts and appliances. |

| Cellulose Acetate | Polymer | High clarity, good chemical resistance, used in eyewear and packaging. |

| Cellulose Acetate Butyrate | Polymer | Improved toughness and impact strength, used in coatings and films. |

| Cellulose Acetate Propionate | Polymer | Lower density, higher transparency, for eyewear frames. |

| Ethylene Vinyl Acetate | Polymer | Flexibility, resilience, used in foam products and flexible tubing. |

| High Modulus Polyethylene (HMPE) | Polymer | Extremely high strength-to-weight ratio, used in ballistic protection. |

| Ionomer | Polymer | Good impact properties and optical clarity, used in packaging films and golf ball covers. |

| Mica-Reinforced Polypropylene | Polymer | Enhanced stiffness and temperature performance, for automotive parts. |

| Modified Acrylic | Polymer | Altered properties for impact resistance or flow, for automotive and signage. |

| Nylon – Transparent | Polymer | High strength and transparency, for high-performance applications. |

| Nylon – Type 6 (Homopolymer) | Polymer | Good wear resistance, used in fibers and engineering plastics. |

| Nylon – Type 66 | Polymer | Higher melting point and strength than Type 6, for mechanical components. |

| Nylon (Type 66 – 33% Glass) | Polymer | Glass fiber reinforcement for enhanced stiffness and strength. |

| PC-ABS | Polymer | Blend of polycarbonate and ABS for high heat resistance and toughness. |

| Phenylene Oxide | Polymer | High dimensional stability and electrical insulating properties. |

| Poly(trimethylene terephthalate) (PTT) | Polymer | Good chemical resistance, used in fibers and textiles. |

| Polyallomer | Polymer | Enhanced stress-crack resistance, used in film and packaging applications. |

| Polyamid 12 (PA12) | Polymer | Good chemical resistance, low moisture absorption, used in tubing and coatings. |

| Polyaryl – Ether | Polymer | High thermal stability and resistance to oxidation, used in electronics. |

| Polybutylene | Polymer | Good flexibility and creep resistance, used in piping systems. |

| Polycarbonate | Polymer | High impact strength and clarity, used in eyewear and bulletproof glass. |

| Polyester Elastomer | Polymer | Elasticity and chemical resistance, used in medical devices and automotive parts. |

| Polyethylene – High Density | Polymer | Stiffness, strength, and chemical resistance, used in containers. |

| Polyethylene – Low Density | Polymer | Flexibility and toughness, used in bags and film applications. |

| Polyethylene (Medium Density) | Polymer | Balance of flexibility and strength, for pipes and films. |

| Polymethyl Methacrylate | Polymer | Excellent clarity and UV resistance, used in signs and displays. |

| Polymethyl Pentene | Polymer | Low density and high heat resistance, used in laboratory equipment. |

| Polyoxymethylene | Polymer | High strength, stiffness, and dimensional stability, for precision parts. |

| Polyphenylene Sulfide | Polymer | High temperature and chemical resistance, for automotive and aerospace parts. |

| Polypropylene – (Glass Filled) | Polymer | Reinforced for increased strength and heat resistance. |

| Polypropylene – Copolymer | Polymer | Improved impact strength at low temperatures, for durable goods. |

| Polypropylene – Flame Retardant | Polymer | Flame resistance for safety applications. |

| Polypropylene – Homopolymer | Polymer | General-purpose with high chemical resistance and weldability. |

| Polystyrene – General Purpose | Polymer | Versatile for low-cost applications, used in packaging and disposables. |

| Polystyrene – High Impact | Polymer | Improved impact resistance, used in appliances and consumer products. |

| Polystyrene – Medium Impact | Polymer | Balance of clarity and impact resistance. |

| Polysulfone | Polymer | High temperature resistance and strength, for medical and electrical applications. |

| Polyvinyl Chloride – Flexible | Polymer | Versatile, used in hoses, tubing, and inflatable structures. |

| Polyvinyl Chloride – Rigid | Polymer | Good chemical and mechanical properties, used in pipes and fittings. |

| Polyvinylidene Fluoride | Polymer | Excellent chemical, UV, and weather resistance, used in coatings. |

| Styrene – Acrylonitrile (SAN) | Polymer | Good chemical resistance and rigidity, for kitchenware. |

| Styrene Butadiene | Polymer | Good abrasion resistance, used in rubber tires and mechanical parts. |

| Styrenic Terpolymer | Polymer | Customized properties for special applications. |

| Synthetic Elastomer | Polymer | Engineered for flexibility and resilience, used in seals and gaskets. |

| Talc-Reinforced Polypropylene | Polymer | Improved stiffness and heat resistance, for automotive and home appliances. |

| Thermoplastic Polyester (PBT) | Polymer | Good mechanical and electrical properties, for electronic connectors. |

| Thermoplastic Polyester (PETG) | Polymer | Easy to form, high toughness, for packaging and medical devices. |

| Thermoplastic Polyurethane | Polymer | Versatile elastomer, for footwear and automotive interiors. |

| Thermoplastic Rubber | Polymer | Combines the processability of plastics with the elasticity of rubber. |

| Urethane Elastomer (Polyether) | Polymer | High wear resistance, used in performance coatings and films. |

| Acrylonitrile Styrene Acrylate (ASA) | Polymer | UV resistance and mechanical properties, for outdoor applications. |

Additionally, our specialization doesn’t stop at polymer detection; we are consistently enhancing our technology to deliver the most advanced tools for the identification and analysis of a wide spectrum of polymers.

Access the Drug Checking Solutions List here, the Cannabis Solutions List here and the Law Enforcement list here; discover the versatility and precision that our technology offers.

Conclusion

At the heart of our service is the commitment to provide solutions that are tailored to the unique challenges and requirements of each industry and use case. We recognize that every sector has specific materials to analyze and distinct operational demands. Our expertise lies in developing solutions that are uncomplicated, swift, and accurate, designed to meet your specific needs. With our advanced NIR spectroscopy technology, we are not just offering a tool; we are providing a pathway to more efficient, cost-effective, and environmentally responsible waste management, recycling processes and plastic production.

To delve further into the world of spectroscopy and discover the full capabilities of NIRLAB’s technology, we invite you to explore our other insightful articles, here. For personalized inquiries, reach out to us at contact@nirlab.com.

NIRLAB // Just Truth